Vaccines have become critical in addressing the worldwide health catastrophe during the COVID-19 epidemic. Vaccine manufacture, transportation, and administration are essential to control the virus. Nevertheless, the success of these stages depends on the efficiency of the vaccine carrier boxes and cold boxes. These overlooked heroes ensure vaccines reach their intended users efficiently and securely.

Vaccine carrier boxes are customized containers that deliver vaccines between their producer to the end user. They are often built of insulated components that serve to maintain the internal temperature of the vaccinations throughout shipment. This is especially crucial for vaccinations that require a specified temperature spectrum for stability.

An effective cold chain system is crucial for safely transporting pharmaceutical products, notably vaccines and other temperature-dependent items. A cold-chain system is a collection of temperature-controlled supply chain procedures, including storage, packing, and delivery. This mechanism ensures that medications retain their potency and purity while being transported from the manufacturing site to the ultimate consumer.

The cold chain system comprises numerous pieces of equipment, such as vaccine carrier boxes and cold boxes, that help ensure the authenticity and effectiveness of pharmaceutical items.

Parameters to Look For:

When selecting vaccine carrier box from this category, consumers of insulated boxes and their procurement agents should keep the following considerations in mind:

Vaccine storage capacity

Each product’s vaccine storage capacity is described on individual product information sheets. The quantity and kind of vaccine that must be transported will be decided by the cold or vaccine carrier box’s intended programmatic usage. Passive equipment is non-powered systems that chill the vaccination chamber with ice packs.

Freeze-preventive vaccine carrier boxes

For Expanded Programmes on Immunisation (EPIs) that use a frozen water pack strategy, freeze-preventive vaccine carrier boxes must be considered. These freeze-preventive carrier boxes shield vaccines from freezing temperatures, eliminating the need for ice-pack conditioning, and providing a long cold life. (At a constant average temperature of +43°C, the cold life is calculated from the moment the lid of the container is closed until the ambient temperature of the vaccine preservation compartment’s highest temperature first exceeds +10°C.)

Cold boxes that avoid freezing are being developed and should provide comparable benefits. The inclusion of freeze-prevention barriers between the ice packs and the vaccines may limit the storage volume of these items.

Cold/warm life

The item’s product data sheets provide three categories of cold/warm life, which show the duration that a cold box/vaccine carrier box sustains a safe ambient temperature throughout shipment.

Weight

Vaccine carrier boxes have been developed with an acceptable full load weight of 8 kg or less and cold boxes with a maximum weight of 50 kg or less. However, in practice, the maximum allowed loaded weight is decided by the mode of transport: car, animal, bicycle, or hand. A worker can’t be expected to lift a burden of more than 25 kg for reasons related to safety and health, and some employees may find this amount excessive. Larger cold boxes might need the assistance of two individuals to lift.

Durability

End-users and purchasing agents should think about the circumstances to which the tightly sealed container will be subjected. For a container delivered by truck over rough terrain, durability could prove more essential than weight. The opposite is true for hand-carried boxes when weight and handling comfort are more crucial.

Vaccine carrier boxes can either be constructed of hard plastic or have a smooth canvas/PVC bag wrapped over the insulated walls. Soft, canvas-type carriers, according to experience, have a shorter life period; they are prone to wear and tear due to weather conditions, and the hooks and straps dissolve with time. The data sheets provide a warning regarding their short operating life. Backpack vaccination carriers are presently available and provide ergonomic benefits.

Foaming components

Products that employ cyclopentane as an insulation foaming component are considered more ecologically friendly than those that use R141b. CFC-containing products are no longer permitted for pre-qualification under WHO PQS criteria.

Water Packs

Check sure water packs are included before placing your purchase. If these items are not included, choose the suitable water-pack type to fit the selected insulated container and purchase them together. The product specifications define the number and kind of water-pack models required. Consider buying two sets to ensure that one may be frozen or chilled while the other is in use.

Water-pack standardization

Whenever feasible, buy cold boxes and vaccination carriers that use only one dimension for the water pack and use them throughout the programme. This streamlines distribution management and eliminates the usage of water packs unsuited to fit the available cold boxes and vaccination carriers.

Cost

Insulated boxes are hefty, and transportation fees can frequently account for a significant amount of the overall delivered price. Before making a final selection, consider the purchase pricing (EXW) or the transportation cost. Choose something that meets programme criteria at the lowest possible price.

Keeping Vaccines Cool During The Vaccination

The foam pad insert is included with a variety of vaccination carriers. This acts as a temporary cap to keep vaccines cold and a surface to grip to safeguard vaccine vials during immunization sessions. The insert is a basic piece of comfy foam that fits snugly into the carrier’s “neck” above the ice packs and underneath the lid.

Removing an ice pack off the carrier and placing the reconstituted container in the hole molded into its surface is no longer suggested. Contacting freeze-sensitive vaccinations with an ice pack may result in vaccine potency loss.

Packing the Vaccines in a Vaccine Carrier Box

The correct packaging of a vaccine carrier box is critical for keeping vaccines at the proper temperature throughout shipment. Fill ice packs to the stated level with the water, verify the water level before use, insert the stopper and tighten the lid snugly, and guarantee the ice pack isn’t leaking. Place the ice pack in the deep freezer after wiping it dry.

Place ice packs out in the open up until liquid water is evident. Shake the ice pack and listen for ice movement inside the ice pack to see whether it has been conditioned. Unconditioned ice packs may harm freeze-sensitive vaccinations.

Load the vaccine carrier box using four conditioned ice packs against the carrier’s edges and the plastic bag comprising all vaccines & diluents in the center. Place vaccination labels in containers or polythene bags to protect them from breakage or wear. Only use conditioned freezing packs with the vaccine carrier box, specially developed to keep the vaccine at the right temperature throughout transit.

Collect vaccinations in the carrier during the session day to reduce exposure to temperature variations. To avoid temperature variations, close the lid snugly and securely. Finally, after each use, maintain the internal components of the vaccine carrier box fresh and dry to prevent pollution and guarantee the vaccines remain viable for future use.

Vaccines must be handled correctly to ensure their safety and effectiveness. Use suitable temperature monitoring equipment to monitor fluctuations in temperature in the carrier to ensure proper handling. When transporting a significant amount of vaccinations, compact coolers and lightweight carriers having tiny wheels may make a considerable difference in ease.

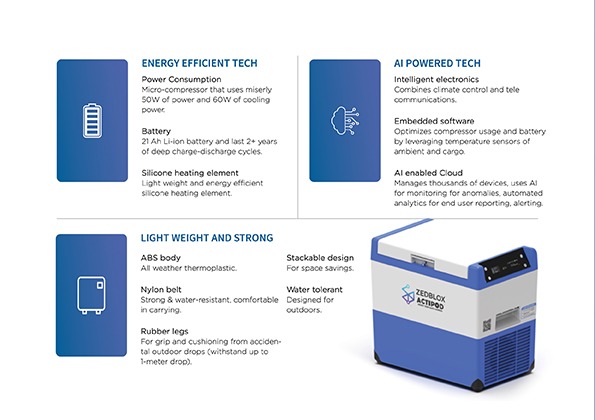

ZedBlox ActiPod is a suitable vaccine carrier box for such a purpose, as it provides remote real-time temperature and location monitoring and is battery-powered. This removes the demand for ice and gel packs, resulting in a safe and regulated environment for vaccine distribution. ZedBlox ActiPod’s sturdy yet lightweight design makes it an ideal outdoor carrier.