Vaccine Carriers & Cold Boxes

The pharmaceutical industry relies heavily on temperature-sensitive products, such as vaccines, to ensure public health and safety. These products require strict temperature control throughout their entire supply chain, from manufacturing to final delivery. Maintaining a specific temperature range, known as the “cold chain,” is essential for ensuring the efficacy and safety of these products. Temperature monitoring is crucial in ensuring the effectiveness of the cold chain. This is where vaccine carriers and cold boxes play a crucial role. Vaccine carriers and cold boxes are designed to maintain the temperature of temperature-sensitive products within a specific range during storage and transportation. These tools play a critical role in ensuring that vaccines and other temperature-sensitive products remain safe and effective.

What are Vaccine Carriers and Cold Boxes?

In the midst of the COVID-19 pandemic, vaccines have become the key to ending the global health crisis. The production, distribution, and administration of vaccines are crucial steps in the fight against the virus. However, the success of these steps depends on the effectiveness of the vaccine carriers and cold boxes. These unsung heroes play a crucial role in ensuring that vaccines reach their intended recipients in a safe and effective manner.

Vaccine carriers are specially designed containers that are used to transport vaccines from the manufacturer to the end user. They are typically made of insulated materials that help to maintain the temperature of the vaccines during transportation. This is particularly important for vaccines that require a specific temperature range for stability.

Cold boxes, on the other hand, are refrigerated containers that are used to store and transport vaccines. They are equipped with cooling mechanisms that help to maintain a constant temperature within a specific range. Cold boxes are essential for the storage and transportation of vaccines that require refrigeration. Vaccine carriers are smaller than cold boxes and are easy to carry.

Cold Chain Heroes: Vaccine Carriers and Cold Boxes in Safe Pharmaceutical Transport

When it comes to the safe distribution of pharmaceutical products, particularly vaccines and other temperature-sensitive items, a well-functioning cold chain system is critical. The cold chain system is a series of temperature-controlled supply chain steps that include storage, packaging, and shipping services. This system maintains the potency and purity of pharmaceuticals while transporting them from the point of manufacture to the final consumer.

The cold chain system is made up of various pieces of equipment, including vaccine carriers and cold boxes, which are instrumental in ensuring the integrity and efficacy of pharmaceutical products. In this article, we will discuss the role of vaccine carriers and cold boxes in cold chain transport and temperature monitoring.

Vaccine carriers are lightweight containers designed for the sole purpose of storing and transporting vaccines. They are frequently used to transfer vaccines to vaccination sites from centralized storage facilities or to transport a small number of vaccinations for community outreach programs. Vaccine carriers typically have insulation to reduce temperature swings and ice or gel packs to maintain a constant temperature. They are also small and compact, taking up minimal space when filled with syringes or vials of vaccine.

Vaccine carriers have a limited storage volume, ranging from 0.8 to 3.4 liters. They are divided into two groups based on the range:

Shorter journeys: up to 15 hours of cold storage life at 43 degrees Celsius.

Extended range: up to 30 hours of minimal cold at 43 degrees Celsius.

Cold boxes are larger, more heavy-duty containers designed for transporting a larger quantity of vaccines and other temperature-sensitive products. They are typically constructed of insulated materials and fitted with cooling systems to maintain a constant temperature. Cold boxes are commonly used for transporting vaccines from one fixed vaccine store to another or to healthcare institutions.

Cold boxes come in sizes ranging from 5 to 25 liters and can be divided into two groups based on the range:

Shorter journeys: up to 48 hours of cold storage life at 43 degrees Celsius.

Extended range: up to 96 hours of minimal cold at 43 degrees Celsius.

Cold boxes are particularly useful for longer distances or challenging settings, such as high ambient temperatures or remote areas without access to electricity. Additionally, they serve as interim substitutes for refrigerators in case of malfunction or defrosting.

The Role of Temperature Monitoring

Temperature monitoring is an essential aspect of maintaining the integrity of the cold chain for temperature-sensitive products, such as vaccines. Temperature-sensitive products must be stored and transported within a specific temperature range to ensure their efficacy and safety. Vaccine carriers and cold boxes play a crucial role in maintaining the temperature range of these products during storage and transportation. However, it is equally important to monitor the temperature of these carriers and boxes to ensure that the products remain within the required temperature range.

Temperature monitoring in vaccine carriers and cold boxes involves the use of specialized equipment, such as data loggers and real-time monitoring systems, to measure and record the temperature of the carriers and boxes. These devices are designed to provide accurate and reliable temperature readings, which can be used to ensure that temperature-sensitive products are stored and transported within the required temperature range.

Data loggers are one of the most commonly used temperature monitoring devices in the pharmaceutical industry. These devices are small and portable, and they are designed to record temperature readings at regular intervals. The data can be downloaded from the device and analyzed to ensure that the temperature-sensitive products have been stored and transported within the required temperature range.

Real-time monitoring systems are another popular temperature monitoring device. These systems use wireless sensors to measure and record the temperature of the vaccine carriers and cold boxes in real time. The data is transmitted wirelessly to a central monitoring system, where it can be analyzed in real-time. Real-time monitoring systems provide instant alerts if the temperature of the vaccine carriers or cold boxes falls outside the required range, allowing for immediate action to be taken to prevent damage to the temperature-sensitive products.

Temperature monitoring in vaccine carriers and cold boxes are essential for several reasons. First and foremost, this ensures the efficacy and safety of temperature-sensitive products, such as vaccines. If the temperature of these products falls outside the required range, they can lose their efficacy or even become harmful. Temperature monitoring ensures that the products remain within the required temperature range, reducing the risk of product loss and potential harm to patients.

Temperature monitoring also helps to reduce waste in the pharmaceutical industry. Improper temperature control can lead to the loss of temperature-sensitive products, which not only wastes valuable resources but also reduces the availability of vaccines and other critical medications.

In addition, temperature monitoring helps to ensure regulatory compliance. The pharmaceutical industry is subject to strict regulations regarding the storage and transportation of temperature-sensitive products. Temperature monitoring helps to ensure compliance with these regulations, reducing the risk of fines and other penalties.

Vaccine carriers and cold boxes are critical components of the cold chain system for transporting temperature-sensitive products like vaccines. They play a vital role in maintaining the required temperature range during storage and transportation to ensure the safety and efficacy of these products. The use of vaccine carriers and cold boxes are crucial in the current global health crisis as they help ensure that vaccines are transported safely and effectively to their intended recipients.

It is important to note that temperature monitoring is an essential aspect of maintaining the integrity of the cold chain. Data loggers and real-time monitoring systems are popular devices used in the pharmaceutical industry for this purpose. They are designed to measure and record the temperature of vaccine carriers and cold boxes, providing accurate and reliable temperature readings.

At this point, it is important to take the necessary steps to ensure that vaccine carriers and cold boxes are appropriately utilized in the transportation and storage of temperature-sensitive products. With the critical role that vaccine carriers and cold boxes play in ensuring the safety and efficacy of vaccines, it is crucial to use high-quality products and temperature monitoring systems.

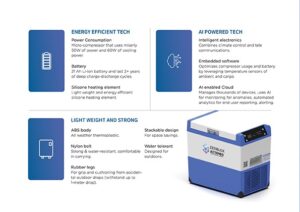

ZedBlox ActiPod ensures the safety and effectiveness of temperature-sensitive products during transportation and storage, making it a reliable and essential tool for pharmaceutical companies and healthcare institutions. Contact us today to learn more about our product and how it can help you maintain the integrity of your cold chain.

References:

https://www.sciencedirect.com/