In today’s world, the transportation and storage of temperature-sensitive goods have become more important than ever before. Its critical role in ensuring the safety and quality of temperature-sensitive products, reducing waste and improving sustainability, and responding to emergency situations is undeniable. The COVID-19 pandemic has highlighted the critical role of cold chain logistics in delivering essential medical products safely and effectively. However, the importance of cold chain logistics extends far beyond the current health crisis.

The global demand for temperature-controlled transportation and storage has driven the growth of the cold chain logistics industry in recent years. Proper temperature control and monitoring are essential to maintaining the safety and quality of perishable goods such as food, medications, vaccines, and other temperature-sensitive biological products. In addition, cold chain logistics enables the transportation of goods across great distances and international borders, opening up new markets and opportunities for global trade.

Despite the critical importance of cold chain logistics, challenges exist in ensuring its effective implementation. These challenges include the cost of infrastructure, the lack of skilled personnel, and the need for effective quality control measures. Hence it is crucial to understand and explore the importance of cold chain logistics in the present world, its critical role in ensuring the safety and quality of temperature-sensitive products, and the challenges that must be addressed to ensure its successful implementation.

WHAT IS COLD CHAIN LOGISTICS?

Cold chain logistics refers to the transportation and storage of temperature-sensitive goods such as pharmaceuticals, vaccines, and other temperature-sensitive products, in a controlled environment to ensure their quality and integrity are maintained throughout the supply chain.

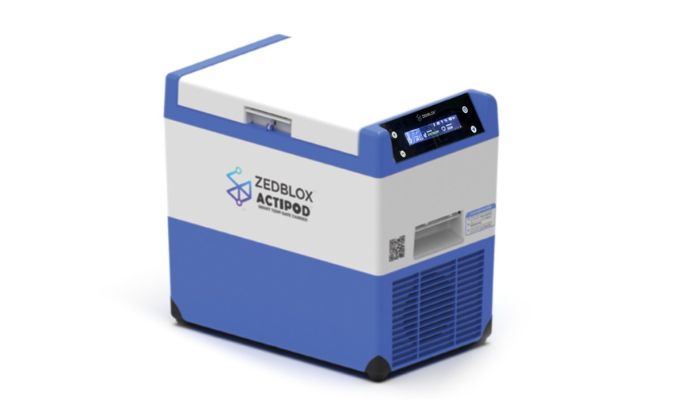

The cold chain logistics process involves the use of specialized equipment and transportation methods such as refrigerated trucks, containers, and warehouses that are equipped with temperature-controlled environments. The goal is to maintain the temperature of the goods within a specific range, depending on the product.

Temperature monitoring is a critical aspect of cold chain logistics as it allows for the tracking of the product’s temperature throughout the supply chain. This ensures that the product remains within the required temperature range and is not exposed to temperature fluctuations that can affect its quality, potency, or safety. Temperature monitoring devices such as data loggers and temperature sensors are used to monitor the temperature of the goods during transportation and storage. These devices provide real-time temperature data that can be monitored remotely, enabling quick interventions to be made in case of any temperature deviations.

Effective cold chain logistics can be the difference between a product’s success or failure, especially for temperature-sensitive biological products, vaccines, and pharmaceuticals. Any deviation in temperature during transportation and storage can result in spoilage, reduced shelf life, or even rendering the product ineffective or harmful to consumers.

The Vital Role of Cold Chain Logistics in the Medical Industry

The cold chain system ensures the quality and safety of sensitive products, including vaccines, blood products, drugs, and medical devices that contain biological materials. The cold chain is a life-saver in the medical industry as it preserves the efficacy and potency of these critical products, which are often the difference between life and death.

Vaccines are among the most essential products that require a cold chain. Vaccines need to be stored at specific temperatures to maintain their efficacy. Any deviation from the recommended temperature range can lead to a loss of potency and render the vaccine ineffective. This can have disastrous consequences, especially in the case of diseases that can be prevented by vaccination. The cold chain ensures that vaccines are stored and transported at the right temperature from the manufacturer to the point of administration.

The cold chain also plays a crucial role in the storage and transportation of blood products. Blood and blood products need to be stored at specific temperatures to prevent the growth of bacteria and other pathogens that can cause infections. Any contamination of blood products can result in severe complications for patients who receive them. The cold chain ensures that blood products are stored and transported at the right temperature, minimizing the risk of contamination and ensuring the safety of patients.

The importance of the cold chain extends to the storage and transportation of drugs that are used to treat life-threatening conditions. These drugs are often sensitive to temperature and need to be stored at specific temperatures to maintain their potency. If the drugs are not stored correctly, they could lose their effectiveness, resulting in a delay in treatment or even death.

The cold chain ensures that drugs are stored and transported at the recommended temperature range, preserving their efficacy and potency and acting as an indispensable system in the medical industry, ensuring the safety and efficacy of sensitive products. Without the cold chain, vaccines, blood products, drugs, and medical devices that contain biological materials could become contaminated or lose their potency, leading to severe consequences for patients.

A Closer Look at the Cold Chain Distribution: Understanding the Process

The cold chain distribution process involves a series of interconnected steps that begin with the manufacturer and end with the delivery of the product to the end user. Here is a breakdown of how the cold chain distribution process works:

-

Product Manufacturing

The manufacturer produces sensitive products, such as vaccines, blood products, or drugs, in a controlled environment and packaging. The product is stored in temperature-controlled conditions to maintain its efficacy and potency.

-

Pre-Cooling and Pre-Shipment Preparation

The product is pre-cooled in a temperature-controlled environment to stabilize its temperature. It is then packaged with temperature-monitoring devices, such as data loggers, to track its temperature during transportation.

-

Transportation

The product is transported in a temperature-controlled vehicle, such as a refrigerated truck or container. The temperature of the vehicle is continuously monitored, and any deviation from the recommended temperature range triggers an alarm to alert the driver and the logistics team. The driver is trained to handle sensitive products and to take appropriate measures in case of a temperature excursion.

-

Warehousing and Storage

The product is stored in a temperature-controlled warehouse or storage facility until it is ready for distribution. The warehouse is equipped with temperature monitoring systems to ensure that the product is stored at the correct temperature range.

-

Distribution and Delivery

The product is distributed to healthcare providers, hospitals, clinics, or other end-users through a temperature-controlled delivery network. The delivery vehicle is equipped with temperature monitoring devices to track the temperature of the product during transportation and the delivery driver is trained to handle sensitive products and to take appropriate measures in case of a temperature breach.

-

Monitoring and Feedback

The logistics team continuously monitors the temperature of the product during transportation and storage and ensures that it remains within the recommended temperature range. They also gather feedback from end-users to improve the cold chain distribution process.

The cold chain distribution process is a complex and interconnected system that ensures the quality and safety of sensitive products, such as vaccines, blood products, and drugs. The process involves temperature-controlled transportation, warehousing, and storage, as well as continuous monitoring and feedback. Any deviation from the recommended temperature range can result in a loss of potency and render the product ineffective, which can have disastrous consequences for patients. Therefore, it is essential to maintain the cold chain distribution process to ensure the safety and efficacy of these vital products.

The Key Elements of Cold Chain Distribution

Effective cold chain distribution involves a range of key elements, each of which plays a vital role in ensuring the safety and quality of the products being transported which includes:

-

Cooling systems

Cooling systems are essential to maintaining the required temperature for perishable products during transportation. These systems ensure that the products are kept at a safe temperature until they are transferred to the next stage of processing. There are different cooling methods, such as refrigeration, dry ice, or gel packs, that can be used depending on the product being transported.

-

Cold storage

Cold storage is a critical component of cold chain distribution. It involves storing perishable items at low temperatures to extend their shelf life and ensure their safety for use and consumption. There is various cold storage equipment available, such as refrigerated shipping containers, cold rooms, cold boxes, and vaccine carrier box, that can be used depending on the product’s temperature requirements.

-

Monitoring

Monitoring is necessary to ensure that the environmental conditions, such as temperature and humidity, are within the required range during transportation and storage. Monitoring devices, such as data loggers or temperature sensors, can be used to monitor the cold chain components’ whereabouts and provide real-time information about the products’ conditions.

-

Transport

Proper transportation is crucial to maintaining the integrity of perishable goods during the distribution process. Transport methods can vary depending on the product being transported, such as air, sea, or land transportation. It is essential to ensure that the products are transported at the correct temperature and without damage to meet end-users demands.

-

Cold Processing and Distribution

Cold processing and distribution centers are where suppliers deliver their loads to be combined and transported to their final destinations. These facilities also assist with the unloading of items from various locations and the consolidation of shipments back to suppliers. By doing so, they help firms streamline their operations; lower transportation expenses, and enhance inventory management systems.

Challenges in Cold Chain Logistics

Maintaining the integrity of the cold chain distribution process is vital for ensuring the safe delivery of temperature-sensitive products. Any disruption in temperature control can result in the degradation of the products, which can pose a risk to public health. Some of the most pressing concerns in cold chain distribution that all stakeholders include:

-

Disruption in Temperature Regulation

Proper temperature regulation is crucial in the cold chain distribution process. Failure to maintain the required temperature range can compromise the efficacy and safety of the products. It is, therefore, essential to ensure that cooling systems are functioning correctly, and the products are continuously monitored to guarantee that they remain within the specified temperature range.

-

Human Error and Negligence

Inadequate training, carelessness, and non-compliance with established protocols can lead to human error, resulting in product damage or deterioration. Examples of human errors include handling damaged containers, leaving refrigeration units open during delivery, and erroneous paperwork causing unwarranted detention or delay.

-

Contamination Issues

Freezers and refrigerators in the cold chain process can serve as breeding grounds for bacteria and other microorganisms if they are not adequately maintained or repaired. Contamination can result in the degradation of the product’s quality and pose a risk to public health. It is critical to ensure that all refrigeration facilities are appropriately monitored to prevent mold growth and contamination.

-

Transportation and Infrastructure

Transportation and storage of temperature-controlled products require specialized equipment and facilities that are expensive to build and maintain. In many developing countries, the lack of adequate infrastructure poses a significant challenge in delivering temperature-controlled products to remote areas.

-

Security and Theft

Temperature-controlled products are often high-value and attractive targets for theft. The risk of theft increases during transportation and storage, particularly in countries with poor security infrastructure.

Since cold chain logistics is a critical component of global supply chains, ensuring the safety and efficacy of temperature-sensitive products is imperative that the industry overcomes these challenges through innovation, collaboration, and a commitment to sustainability.

The cold chain logistics process plays an essential role in ensuring the safety and efficacy of temperature-sensitive products, especially in the medical industry. Proper temperature control and monitoring are necessary to maintain the quality and integrity of these temperature goods. However, the challenges faced in the effective implementation of cold chain logistics, such as the cost of infrastructure, lack of skilled personnel, and quality control measures, cannot be ignored.

These challenges must be addressed to ensure the successful implementation of the cold chain logistics process. The COVID-19 pandemic has shown that the cold chain logistics system is essential in delivering essential medical products safely and effectively. The global demand for temperature-controlled transportation and storage is increasing, and addressing the challenges in the cold chain logistics system will ensure its successful implementation, leading to reduced waste and improved sustainability in the transport of temperature-sensitive products.

The need to overcome the challenges faced by cold chain logistics is crucial to maintain the quality and safety of temperature-sensitive products, minimize waste, and provide a sustainable transport system that meets the needs of the present and the future.

References:

https://www.supplychainbrain.com/